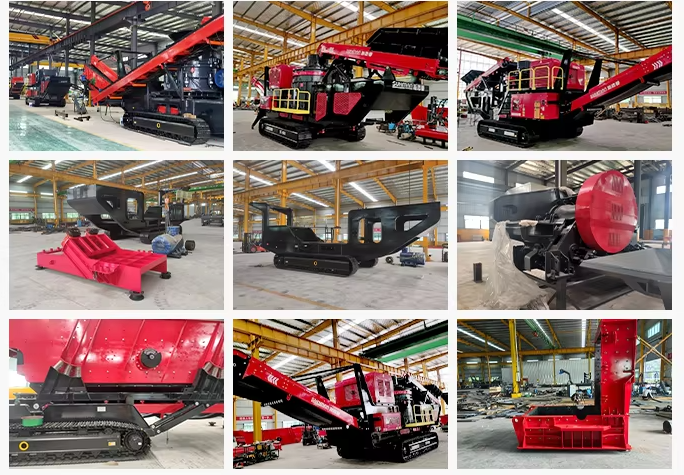

The SUHMAN SE-1060 is a 200–250 TPH track-mounted mobile jaw crusher engineered for hard rock quarrying and construction & demolition (C&D) recycling. With a 1060×700 mm jaw, integrated vibrating feeder and compact transport dimensions, it combines high output with easy relocation between job sites. On-site primary crushing reduces truck haulage and helps contractors, quarries and equipment dealers lower their cost per ton while keeping production flexible.

With more than 15 years of experience building crushers for quarries and mines, SUHMAN has focused the SE-1060 on real hard-rock work instead of brochure figures. Whether you run a granite quarry or an iron ore project, this unit is built to handle long shifts and rough conditions.

Why the SUHMAN SE-1060 Excels in Hard Rock Crushing

Jaw and Crushing Chamber for Abrasive Rock

The SE-1060 uses a 1060×700 mm jaw with a deep crushing chamber and high-manganese liners. It is built for abrasive, high-strength stone and ore, not just soft limestone. In typical quarry work it handles feed up to about 700 mm and can be set in the 80–180 mm discharge range, which matches most secondary cone crushers and screening setups.

“…suitable for hard rock quarrying and mining applications.”

Realistic 200–250 TPH in daily work

Total installed crushing power is 139.4 kW, with 110 kW on the main jaw motor. With a 4000×1100 mm vibrating feeder rated for 200–250 t/h, the machine can hold a steady output when it is fed properly. On material with a lot of fines, using pre-screening helps keep the jaw from doing unnecessary work and can noticeably improve throughput and fuel use.

Made to move around the site

The crusher sits on an LDZ55-3657 track chassis, so it can crawl over rough ground and climb slopes up to around 35°. Hydraulic support legs help it settle into working position quickly; on a prepared pad, setup is usually a matter of minutes, not hours. Transport size is about 14.85×3.1×3.9 m, so in many regions it can go on the road without stripping off major components, which keeps moves simple and cheaper.

Protection and layout options

A de-ironing separator protects the line by pulling out tramp steel before it reaches downstream equipment. The plant is laid out so it can work on its own or be dropped into a multi-stage line with cone crushers and screens. The electric drive keeps energy use under control, and an optional diesel generator makes it easier to run the unit on remote sites without a stable grid supply.

Updated Technical Specifications – SUHMAN SE-1060 (2025 Model)

| Parameter | Specification |

|---|---|

| Model | SE-1060 |

| Capacity | 200–250 t/h (hard rock) |

| Max Feed Size | 700 mm |

| Discharge Range | 80–180 mm (adjustable) |

| Jaw Crusher | 1060×700 mm inlet; 110 kW power |

| Total Power | 139.4 kW (crushing operations) |

| Vibrating Feeder | 4000×1100 mm; 4.5×2 kW motors |

| Weight | 44 tons (complete unit) |

| Transport Dimensions | 14.85 × 3.1 × 3.9 m |

| Hopper Volume | 3 m³ |

| Conveyor Stacking Height | Main: 3000 mm; Tail: 2350 mm |

Power Options – Choose What Suits Your Site Best The SE-1060 is available in two configurations to match any job site condition:

- Single Power Version – Connects to external grid power (380–480 V). Ideal for quarries or recycling yards with stable electricity supply – lower operating costs.

- Dual Power Version (Most Popular) – Switch seamlessly between diesel generator and grid power. Perfect for remote mines or projects without reliable electricity.

Engine & Emission Compliance

- Standard: High-quality Chinese brand engine (China Stage III)

- Optional upgrades: China Stage IV, EPA Tier 4 Final, or Euro Stage V – fully compliant with regulations in Europe, North America, Australia, Middle East, and Southeast Asia.

Fast Delivery & Comprehensive After-Sales Support

| Item | Details |

|---|---|

| Delivery Time | 20–25 working days after receiving deposit |

| Warranty | 12 months (critical components) |

| Spare Parts | Full set of wear parts included; lifetime supply guaranteed |

| Commissioning | Our engineers fly to your site for installation, commissioning, and hands-on training until your team operates independently |

| Ongoing Support | Free remote video diagnosis 24/7 If needed, we dispatch engineers worldwide (costs covered under warranty) |

Real-World Reliability from Global Users

Deployed in over 80 countries—from Australian basalt pits to Brazilian iron ore mines—the SE-1060 has logged millions of hours with 95% uptime. Customers praise its low wear rates (up to 50% less than competitors) and consistent cubical product shape, ideal for aggregates in highways, railways, and construction recycling.

Applications Tailored for Your Operation

- Mining & Quarrying: Primary crushing of granite, basalt, and ore tailings for high-volume output.

- Infrastructure Projects: On-site processing for railway ballast and bridge aggregates.

- Recycling: Efficient breakdown of construction waste, including reinforced concrete with rebar removal.

SUHMAN® – Official Website: https://suhmancrusher.com

Explore Full Details: https://suhmancrusher.com/mobile-jaw-crusher-for-hard-rock/

Contact for Quote & Layout: Email: info@suhmancrusher.com

SUHMAN – Engineered Tougher. Crushing Smarter.