7 Stone Crusher Types: How to Pick the Best for Your Project

Release time: 2025-03-09

Stone crushers are essential machines in industries such as construction, mining, and recycling, transforming large rocks into smaller, usable materials. Choosing the right crusher can boost productivity, reduce costs, and ensure high-quality output. In this guide, we’ll dive into the various types of stone crushers, key factors for selecting the best one, and the crushing methods they employ, while spotlighting cutting-edge innovations in crusher technology.

What Is a Stone Crusher?

A stone crusher is a mechanical device that uses energy to break down rocks, concrete, or other materials into smaller sizes tailored to specific needs. These machines are indispensable for processing a wide range of materials—from hard stones like granite to softer minerals—across industries like mining, construction, and demolition. Whether reducing ore for further processing or recycling debris, stone crushers deliver efficiency and versatility.

How to Choose the Right Stone Crusher

Selecting the perfect stone crusher involves evaluating several critical factors to match your operational needs. Here’s a breakdown:

- Material Type and Hardness: Hard materials like granite demand durable crushers such as jaw or cone models, while softer materials may work well with impact crushers.

- Material Size: Large rocks require primary crushers like jaw crushers, whereas smaller stones may need combined crushing and screening systems for precise sizing.

- Moisture Content: Wet materials can clog crushers. High moisture levels may rule out certain models like cone or impact crushers, so assess this carefully.

- Output Size: The desired particle size determines the crusher type and crushing stage—fine outputs often require tertiary crushers.

- Production Capacity: Higher output demands larger machines. Match the crusher’s capacity to your production targets.

- Site Conditions: Terrain and space constraints affect crusher choice. Mobile options, like the Crawler Type Mobile Impact Crusher Produced in China, excel in flexible or remote locations.

7 Main Types of Stone Crushers

Each stone crusher type offers distinct features, benefits, and limitations. Here’s an in-depth look at the seven most common types:

- Jaw Crusher

- Crushing Method: Compression

- Ideal For: Hard, abrasive materials

- Pros: Simple design, high capacity, cost-effective

- Cons: Coarse output, may need secondary crushing

- Innovation: The Dual-core Jaw Crusher enhances performance on tough rocks.

- Cone Crusher

- Crushing Method: Compression

- Ideal For: Medium to fine crushing of hard rocks

- Pros: High efficiency, uniform output, energy-saving

- Cons: Complex maintenance, higher cost

- Innovation: Check out the Efficient and Multifunctional Modular Cone Crusher.

- Impact Crusher

- Crushing Method: Impact

- Ideal For: Medium-hard materials, shaping

- Pros: Cubical output, high reduction ratio

- Cons: Fast component wear with hard rocks

- Innovation: The Modular Impact Crusher for Sand Making excels in sand production.

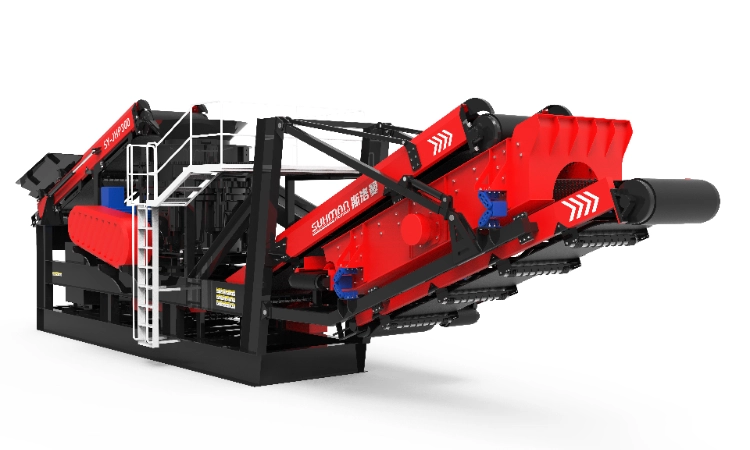

- Mobile Crusher

- Crushing Method: Varies (jaw, cone, impact)

- Ideal For: On-site crushing in remote areas

- Pros: Mobile, integrated, remotely operable

- Cons: Higher initial cost

- Innovation: The Mobile Crushing and Screening Integrated Machine boosts efficiency.

- Sand Making Machine

- Crushing Method: Impact or attrition

- Ideal For: Fine aggregates and sand

- Pros: High efficiency, shaping ability

- Cons: Limited feed size, higher wear

- Hammer Crusher

- Crushing Method: Impact

- Ideal For: Medium to fine crushing of soft materials

- Pros: High reduction ratio, fine output

- Cons: Hammer wear, poor with wet materials

- Roller Crusher

- Crushing Method: Compression and shear

- Ideal For: Medium-hard materials like coal

- Pros: Compact, handles sticky materials

- Cons: Low efficiency, not for hard rocks

Crushing Methods Unveiled

Knowing how crushers break down materials helps you pick the right one. Here are the main crushing methods:

- Compression: Applies pressure to crush hard rocks.

- Impact: Uses high-speed blows for cubical particles.

- Shear and Attrition: Combines pressure and friction for finer results.

- Splitting and Bending: Fractures materials with tensile stress, often in secondary stages.

Most crushers blend these methods for optimal performance.

Multi-Stage Crushing Explained

Achieving the perfect particle size often requires multiple stages:

- Primary Crushing: Breaks large rocks into manageable sizes using jaw or gyratory crushers.

- Secondary Crushing: Refines material further with cone or impact crushers.

- Tertiary Crushing: Produces fine outputs for specific uses with cone or impact models.

Matching the crusher to each stage ensures efficiency and quality.

Emerging Trends in Stone Crusher Technology

Modern advancements are revolutionizing stone crushers:

- Automation & AI: Real-time adjustments enhance output.

- Energy Efficiency: New designs cut power use and costs.

- Wear-Resistant Parts: Advanced materials extend durability.

- Mobile Solutions: Portable, modular units adapt to any site.

Finding the ideal stone crusher means understanding your materials, production goals, and the crushing methods involved. By factoring in these elements and exploring the latest technologies, you can optimize your setup for top performance. Whether it’s a rugged jaw crusher or a flexible mobile unit, this guide equips you with the knowledge to choose wisely.