1. Versatile Application: Recycling & Soft Rock

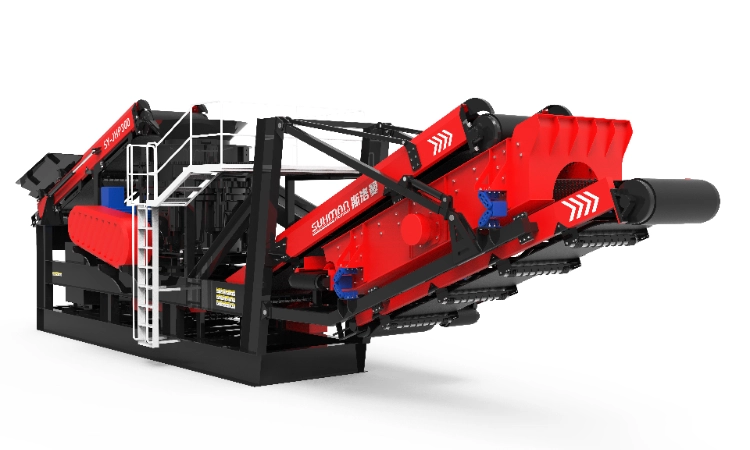

The SF-380D is engineered to handle materials with low-to-medium hardness. It excels in both quarrying and recycling applications, making it the perfect solution for:

- Recycling: Efficiently crushes reinforced concrete, asphalt, and demolition waste.

- Quarrying: Ideal for limestone, gypsum, and coal with a large 1380×970 mm feed opening.

- Large Feed Size: Capable of accepting feed sizes up to 600mm, significantly reducing the need for pre-processing.

2. Superior Product Shape (1214 Impactor)

Equipped with a powerful Model 1214 Impact Crusher (220 kW), this machine delivers high inertia and excellent reduction ratios. Features include:

- Cubical Output: Produces high-quality, cubic-shaped aggregates (0-150mm adjustment range) suitable for highway surface material.

- High Throughput: Machine processing capacity reaches up to 180 TPH, ensuring high productivity for medium-scale projects.

3. Integrated Closed-Circuit System

The SF-380D is a fully self-contained recirculating plant designed for precise sizing:

- Built-in Screen & Return Conveyor: Features a 4000×1540 mm hanging screen. Oversized material is automatically returned to the crusher via the 7000mm return belt for re-crushing.

- Single-Chassis Solution: Weighing 51 tons, this integrated unit combines feeding, crushing, and screening on one track frame, eliminating the need for external screens.

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)

.png)

.png)

.png)

.png)