Crushers and Screening Equipment

Release time: 2025-03-16

1. Introduction

From roads and buildings to everyday gadgets, the materials we rely on often start as massive chunks of rock or waste. Crushers and screening equipment make it possible to process these raw materials efficiently. Crushers reduce large pieces into smaller fragments, while screening equipment separates them into specific sizes for further use. Together, they form the foundation of modern material processing, driving productivity and sustainability.

2. Types of Crushers

Crushers come in different designs, each suited to specific tasks. Here’s a look at the most common types:

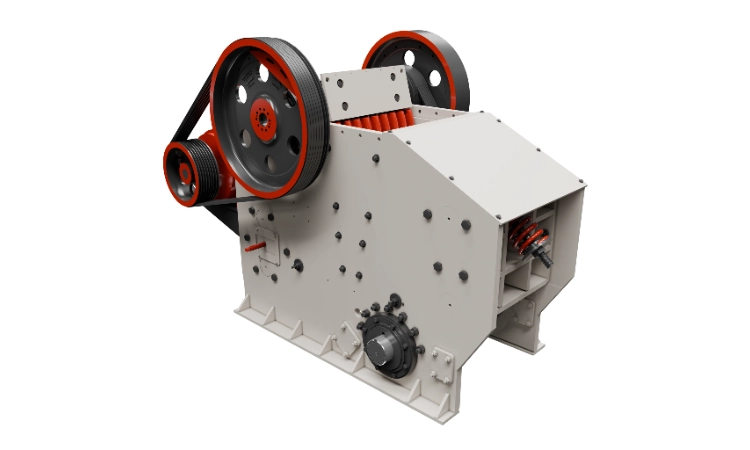

- Jaw Crushers

Built for durability, jaw crushers are perfect for primary crushing. They use two plates to compress hard materials like stone into smaller pieces. Want to know more? Check out how a jaw crusher works. - Cone Crushers

These machines are great for secondary or tertiary crushing, handling medium-hard materials with precision. They’re widely used in mining and aggregate production. - Impact Crushers

Using high-speed impacts, these crushers excel at producing sand, gravel, and recycled materials like construction debris. - Hammer Crushers

Ideal for brittle materials like limestone, hammer crushers shatter materials with rotating hammers, making them popular in cement production.

Struggling to choose? Explore our comparison of jaw vs. cone crushers for clarity.

3. Types of Screening Equipment

Screening equipment ensures crushed materials are sorted accurately. Here are the key types:

- Vibrating Screens

Using vibration, these screens separate materials into different sizes, making them highly adaptable. - Trommel Screens

These rotating drum screens are excellent for initial sorting, especially in construction waste processing. - Scalper Screens

Built for pre-screening, scalper screens remove large chunks before finer sorting. Learn more about what a scalper screen does.

4. Applications of Crushers and Screening Equipment

These machines are indispensable across various sectors:

- Mining: Crushers process ore into smaller pieces, while screens classify it for extraction.

- Construction: They produce aggregates and recycle demolition waste. See how mobile crushers shine in urban projects.

- Aggregate Production: High-quality materials for roads and buildings rely on these machines.

- Recycling: Crushers turn waste like concrete into reusable resources, supporting eco-friendly practices.

For tough jobs, discover how specialized equipment handles hard rock crushing.

5. How to Choose the Right Equipment

Picking the right crusher or screening equipment involves a few key considerations:

- Material Type: Hardness and size dictate the best machine for the job.

- Output Needs: Match capacity and particle size to your project goals.

- Mobility: Mobile crushers suit temporary sites, while stationary ones are ideal for long-term use.

- Reliability: Work with trusted suppliers, like a China mobile crusher manufacturer, for quality assurance.

Need more help? Read our guide on choosing a tracked mobile crusher.

6. Conclusion

Crushers and screening equipment are essential for turning raw materials into valuable resources. By understanding their types, uses, and selection factors, you can optimize your operations for efficiency and cost-effectiveness. Explore our products page or contact us for tailored advice.

More to Explore:

This article offers a comprehensive look at crushers and screening equipment, with internal links seamlessly integrated to provide additional value without disrupting the flow.