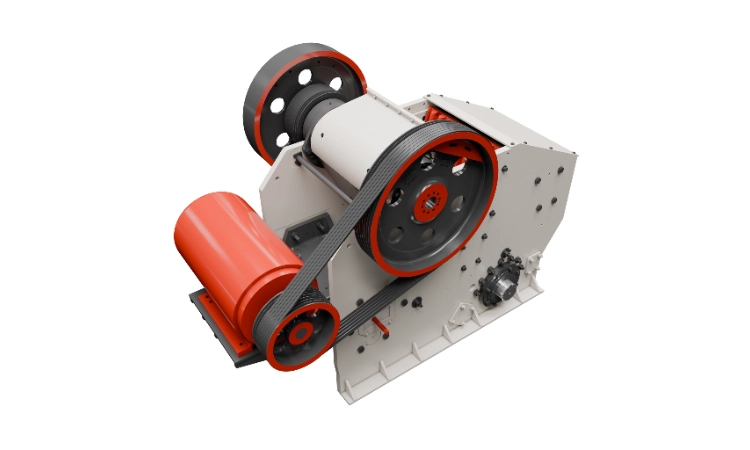

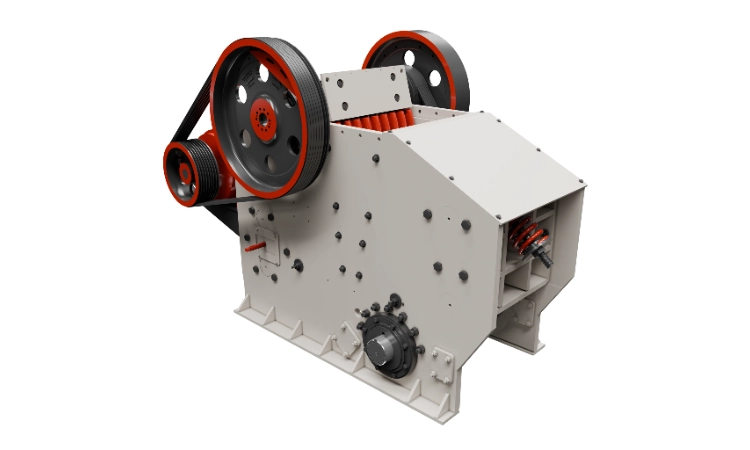

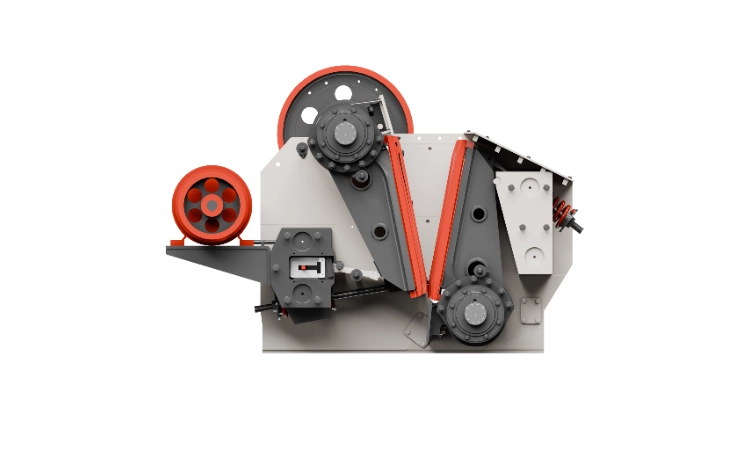

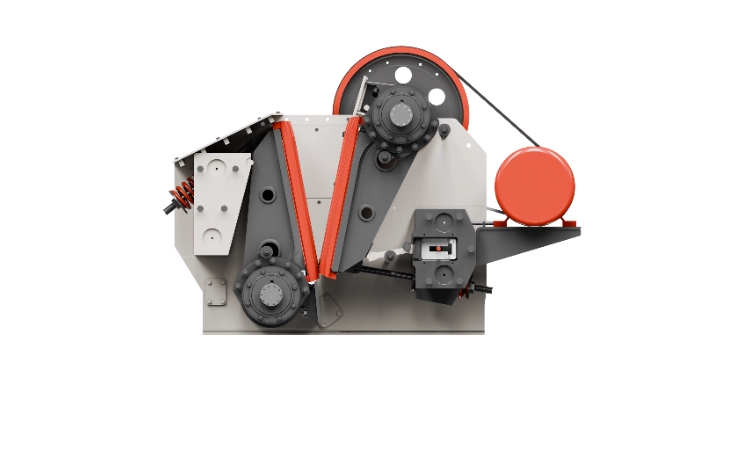

Unique Working Principle: The Dual-Jaw Advantage

The Problem with Standard Crushers: Most conventional compound swing jaw crushers suffer from a common flaw: the crushing stroke decreases as material moves down the chamber. By the time rock reaches the discharge port, the crushing force is minimal, making it difficult to crush material effectively into fine sizes. The SUHMAN Solution: The TZ Series features a patented rotationally symmetrical "V"-shaped double jaw structure. This design introduces an "inverted movable jaw" that provides a full crushing stroke at the discharge end. This ensures that crushing force remains powerful throughout the entire process, from entry to exit. The Result: Unmatched Reduction Ratio This structural optimization delivers a massive performance leap:- High Reduction Ratio: While standard jaws offer a ratio of 3-5:1, the Dual-Core Jaw achieves a ratio of up to 15:1.

- Single-Step Crushing: It can process raw material from 500mm directly down to 40mm in a single pass.

- Efficiency: Capable of achieving production capacities of nearly 100 TPH for fine aggregates, effectively doing the job of both a primary and secondary crusher.

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)

.png)

.png)