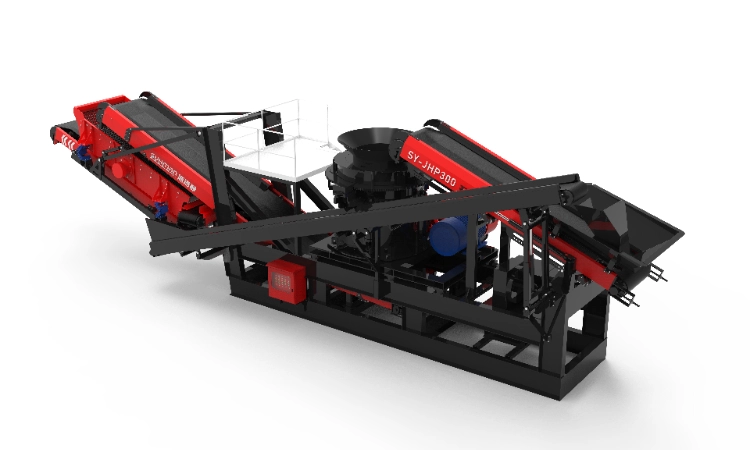

The modular cone crusher offers a high processing capacity and excellent production efficiency. It can be operated independently by a single team or easily integrated with a system configuration team for collaborative operations.

In large-scale sand and gravel aggregate production plants, cone crushers are used to further refine materials that have been initially crushed by jaw crushers, ensuring that the final product meets the specifications for various aggregate sizes.

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)

.png)

.png)

.png)

.png)