From Jaw Crushers to Vibrating Screens: Understanding Aggregate Equipment

Release time: 2025-03-13

Common Crushing and Screening Equipment for Sand and Gravel Aggregates

Sand and gravel aggregates are essential raw materials for construction, infrastructure, and transportation projects. The quality and gradation of aggregate products depend heavily on the efficiency of the crushing and screening processes. In any aggregate production line, the core technologies are crushing and screening. Selecting appropriate crushing and screening equipment is crucial because it directly impacts the final product’s quality, shape, and gradation. Below, we introduce the most common types of crushing and screening equipment used in modern aggregate production, explaining their roles and characteristics.

Crushing Equipment

Crushing equipment is generally categorized by its working principle into compressive crushers and impact crushers. Compressive crushers (like jaw and gyratory crushers) crush material by squeezing it until it breaks, typically producing less fine material but more elongated particles. Impact crushers (including traditional impact crushers, hammer mills, and vertical shaft impactors) use rapid impact to shatter material, yielding good particle shape but often with higher wear on parts. Many crushing plants use a combination of different crushers in multiple stages (usually primary, secondary, and tertiary) to achieve the desired aggregate size and shape. Whether used in a fixed installation or as part of a mobile crushing plant, these crushers form the backbone of aggregate production.

Jaw Crusher

The jaw crusher is a primary crusher known for its simple structure and reliable continuous operation. It features a fixed jaw plate and a moving jaw plate that form a V-shaped chamber. Material is fed into the chamber and crushed as the moving jaw presses it against the fixed jaw. Jaw crushers are favored for their high throughput and ability to handle large, hard materials (e.g., granite, ores) with a relatively low cost of investment and operation.

They perform intermittent crushing (the crushing action stops and starts with each motion of the jaw) and produce a range of particle sizes. Jaw crushers do tend to produce uneven particle shapes (more flat and elongated pieces) and a wider distribution of sizes. However, they seldom clog, even when processing wet or muddy materials, making them well-suited for hard rock crushing and for the primary crushing stage in both stationary and mobile crusher units.

Gyratory Crusher

The gyratory crusher is another primary crusher type, characterized by a high throughput capacity and uniform product output. It has a central conical crushing head that gyrates (rotates in an eccentric motion) within a stationary bowl. As rock enters the top of the gyratory crusher, it is crushed between the mantle (the moving cone-shaped element) and the concave liners (the stationary bowl). Gyratory crushers can accept exceptionally large feed sizes and, when compared to jaw crushers of the same gape (opening) size, can process 2.5–3 times more material per unit time. The output from a gyratory crusher is very consistent in particle size, which can simplify downstream screening. The trade-off for their superior capacity and continuous crushing operation is a higher initial investment and more complex infrastructure (they are tall, heavy machines that require a strong foundation). Gyratory crushers are typically chosen for large-scale aggregate or mining projects where high throughput is needed and space permits. For a more detailed comparison of these two primary crushers, read our article Jaw Crusher vs. Gyratory Crusher.

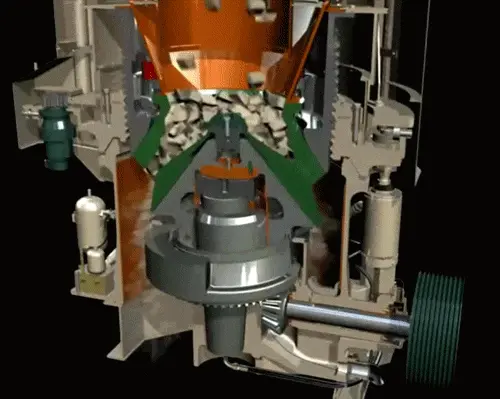

Cone Crusher

A cone crusher is commonly used in secondary or tertiary crushing stages. It operates with a spinning cone (called the mantle) inside a bowl (the concave). The cone crusher provides a strong crushing force and a high crushing ratio, making it capable of handling a variety of materials, including hard and abrasive stone. Cone crushers are valued for their high productivity and reliability in continuous operation. They generally produce more cubic-shaped aggregate than jaw crushers if used in secondary applications.

However, as a fine crusher (tertiary), some cone crusher designs can yield particles with a less optimal shape and a relatively low proportion of fines (crushed sand). Additionally, cone crushers have more complex components like hydraulic systems and an internal support structure, which can make maintenance and repairs more involved. Despite these considerations, cone crushers are widely used in aggregate production worldwide, often as the second stage of crushing after a jaw crusher.

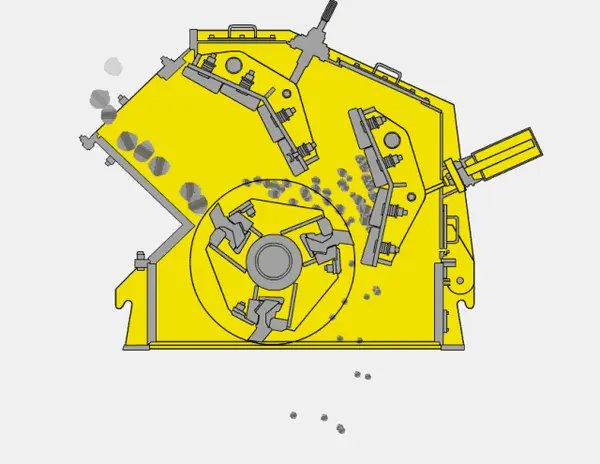

Impact Crusher and Hammer Crusher

Impact crushers and hammer crushers use rapid impacts to break rock and are known for achieving high reduction ratios with good product shape. These two crusher types have similar working principles: material is fed into a crushing chamber and struck by a blow bar (impact crusher) or hammers (hammer crusher) that fling the material against breaker plates or anvils. The impact breaks the material along its natural weak points. The advantages of impact-type crushers include a simpler structure (especially for hammer crushers), the ability to produce a more uniform particle shape, and often a lower capital cost than cone crushers.

They are especially effective for materials that are not too hard or abrasive (for example, limestone or other brittle materials), making them ideal for secondary crushing stages in many aggregate operations. A downside of both impact and hammer crushers is the higher wear and tear on parts like hammers, blow bars, and impact plates; these parts require regular replacement, especially when crushing very hard or abrasive rocks. In modern aggregate plants, impact crushers are commonly used as secondary crushers, while hammer crushers might be used in some cases for primary crushing (e.g., in small plants or for softer materials).

Vertical Shaft Impact Crusher (VSI)

The vertical shaft impact crusher (VSI), often referred to as a sand making machine, is a specialized tertiary or fine crusher that uses a high-speed rotor and anvils or rock beds to fracture material. VSIs are unique in that they can operate in two different crushing modes, often described as “rock-on-rock” and “rock-on-iron.” In a rock-on-rock configuration, the crusher throws material against an enclosed bed of rock, thereby achieving breakage with minimal direct wear on metal parts. This mode is typically used for shaping aggregate particles and is ideal for abrasive materials (like basalt), yielding an excellent particle shape (a cubical product) and a lower amount of flaky pieces. In contrast, the rock-on-iron mode involves throwing the material against hardened anvils or impact plates; this approach tends to achieve higher crushing efficiency and is often used for softer stones (like limestone) or when a higher sand production rate is desired.

Vertical shaft impact crushers are prized for their high production of fine aggregate (manufactured sand) and their ability to improve the overall particle shape of the output. They also have a compact design and usually a lower operational cost in terms of wear-parts replacement, provided the correct mode (rock-on-rock vs. rock-on-iron) is chosen for the material being processed.

Common Crusher Combinations in Aggregate Plants:

- Jaw Crusher + Impact Crusher: A jaw crusher is often used for the primary breakdown of large rocks, followed by an impact crusher for secondary crushing. This two-stage combination can handle a wide variety of material. It offers a broad range of aggregate products and easy adjustment of the ratio of coarse to fine output. This setup is suitable for medium abrasiveness materials and can be scaled up for higher capacity. On the downside, the overall particle shape of aggregates from this combination is decent but not as good as some other methods, and the wear costs (especially in the impact crusher) can be higher compared to using a cone crusher.

- Jaw Crusher + Cone Crusher: In this configuration, the jaw crusher handles the initial reduction of large rocks, and a cone crusher performs secondary (and sometimes tertiary) crushing. This combination is well-suited for high abrasiveness materials (hard rock) and generally produces aggregates with very good shape and a balanced gradation. Wear and tear on the equipment tends to be lower than with an impact crusher, especially for hard stone, which can make it more cost-effective in the long run. However, cone crushers produce less fine material (sand) compared to impact crushers, so if a high volume of sand or very fine product is required, additional equipment (like a VSI crusher) might be needed. Additionally, for very high throughput requirements, multiple cone crushers in parallel might be necessary, since a single cone crusher could become a bottleneck if extremely large capacity is needed.

Screening Equipment

After crushing, screening equipment is used to separate the crushed aggregate into desired size fractions. The effectiveness of the screening stage directly affects the quality and consistency of the final products, as well as the overall efficiency of the operation. There are several types of screening devices used in aggregate production, including stationary grizzlies (fixed bar screens for very coarse material), rotating trommel screens (cylindrical drum screens), roller screens (screens with rotating shafts or disks), and various vibrating screens. Among these, vibrating screens are by far the most commonly used in modern sand and gravel aggregate projects because of their efficiency and versatility. Vibrating screens can handle high capacities and a variety of materials, and they come in different designs such as circular motion, linear motion, and multi-slope (banana screens) to suit different applications. Below, we discuss some common types of screening machines and their features.

Circular Vibrating Screen

The circular vibrating screen (often called a circular-motion screen) is a widely used screening machine characterized by its robust design and the circular motion of its screen media. It typically employs a single-shaft vibrator that generates an elliptical or circular throw of the screen. Circular vibrating screens are appreciated for their high strength, high screening efficiency, and durability. They often can be designed with multiple decks (layers of screens) to sort material into several size categories in one pass.

These screens are relatively simple to maintain, but one drawback is that their bearing and lubrication systems require regular attention (frequent greasing and occasional bearing replacement) due to the continuous circular vibration. Additionally, the vibrating mechanism (exciter or motor) may need periodic replacement or refurbishment after extended operation. Despite these maintenance needs, circular vibrating screens are very common in aggregate production because they provide reliable screening performance and are cost-effective for a broad range of applications.

Linear Vibrating Screen

A linear vibrating screen moves the material in a straight-line motion along the screen surface. This design typically involves two counter-rotating shafts or a dual-shaft mechanism that creates a back-and-forth vibratory motion (instead of a circular throw). The linear motion has some advantages: it tends to be more suitable for fine screening and dewatering applications, since the consistent movement can better convey thin layers of material. Linear screens have a compact, low-profile structure and they operate smoothly with stable vibration. They are also relatively easy to maintain in terms of replacing screen panels and servicing drive motors.

However, linear vibrating screens can be more complex in construction than circular screens, and their vibration amplitude is usually fixed (not easily adjusted on the fly). The motion pattern is uniform across the entire screen, which is good for screening accuracy but can be less energetic for moving oversized material off the screen. Linear screens are commonly used in sand production or in the intermediate screening stages where precise separation and sometimes dewatering (removing moisture from sand) is needed.

Banana Screen

The banana screen (named for its curved shape resembling a banana) is a high-capacity vibrating screen that features multiple sections of screen with different inclinations. Instead of a single flat incline, a banana screen has a deck that starts at a steeper angle and then transitions to shallower angles toward the discharge end, creating a continuous banana-like curve. This multi-sloped design exposes the material to different g-forces, allowing for more efficient screening. The steeper section at the feed end accelerates the material (handling high throughput), while the flatter sections toward the end slow down the material for more refined screening.

Banana screens are known for their high stability, large processing capacity, and long service life. In fact, for the same footprint, a banana screen can process 1.5 to 2 times the capacity of a traditional circular vibrating screen. They are particularly useful in large aggregate plants and mining operations for coarse, medium, and fine screening tasks. Because of their efficiency, a banana screen can sometimes replace multiple traditional screens, which simplifies the process flow.

However, banana screens are larger and more expensive, and they require sufficient installation space and a strong support structure. In the sand and gravel industry, banana screens are often employed when a single machine is needed to handle a very high volume of material across several size fractions efficiently.

Self-Centering Vibrating Screen

A self-centering vibrating screen is a type of vibrating screen where the drive mechanism automatically centers itself during operation. This design typically involves a single drive that allows the screen sub-frame to find its center of mass, reducing the transmission of vibration to the supporting structure. Self-centering screens offer a very strong and aggressive vibration of the screen mesh, which helps prevent material from clogging the apertures (i.e., they are less prone to blinding when screening damp or sticky material). They are also relatively straightforward in terms of structure and easy to adjust for different operating parameters.

One distinct feature is that the screen’s amplitude (the intensity of vibration) can change depending on the load of material. While this self-adjusting amplitude can be beneficial in some cases, it is also a drawback: as the feed rate fluctuates, the varying amplitude may lead to inconsistent screening efficiency. Moreover, during the start and stop phases of operation, a self-centering screen can experience a temporary surge in amplitude. This large amplitude during start/stop requires careful engineering of the screen’s supports, as it can cause additional stress or even damage to the supporting structure or nearby equipment if not managed properly.

Generally, self-centering vibrating screens are used for intermediate and final sizing of medium and small aggregate particles. They are valued for their simplicity and vigorous screening action, especially in conditions where material tends to clog other types of screens.

In addition to the above, there are other specialized screening devices like high-frequency fine screens (for ultra-fine material separation) and bar screens (grizzlies for removing oversize rocks) used in certain applications. Each type has its place in aggregate production, but vibrating screens in their various forms (circular, linear, banana, self-centering, etc.) cover the majority of screening needs in typical sand and gravel operations.

Efficient crushing and screening are critical to producing high-quality aggregates for construction and industrial use. By understanding the strengths and limitations of each type of crushing equipment (jaw, gyratory, cone, impact, hammer, VSI) and screening equipment (vibrating screens like circular, linear, banana, self-centering, etc.), engineers and project managers can design an optimal process flow for their material. In practice, a mix of crushers and screens is usually tailored to the characteristics of the source material (hardness, abrasiveness, moisture content) and the specifications of the final products required.

It’s also worth noting that modern mobile crushing and screening plants integrate these crushers and screens into highly portable units. Whether in a permanent quarry installation or a temporary work site, mobile systems (often track-mounted crawler crushers and screens) provide the flexibility to process materials on-site, which can save on transportation costs and setup time. Many leading manufacturers around the world, including major mobile crusher manufacturers in China, now offer a full range of mobile jaw, cone, and impact crushers along with mobile screening plants. These mobile solutions are built on the same principles described above, with added mobility and quick setup.

Ultimately, selecting the right crushing and screening equipment comes down to understanding the material, the production requirements, and the project constraints. With the optimal combination of machinery, crushing and screening operations can achieve efficient throughput, ideal aggregate sizes, and the desired material quality—whether for small-scale building projects or large-scale infrastructure development.