Granite is a hard igneous rock mainly composed of quartz, feldspar, and mica. With a Mohs hardness of 5–7, it features high strength, corrosion resistance, and excellent wear resistance. After being processed into sand, granite produces well-shaped and uniformly sized particles — an ideal construction material that meets the strict requirements for high-quality aggregates in modern engineering projects.

This article discusses the sand yield rate of granite sand making, the factors affecting it, and the typical configuration of a granite sand production line.

1. Granite Sand Yield and Influencing Factors

The sand yield of granite depends on several factors, including rock properties, feed size, crushing method, and sand-making equipment.

According to industry data, the sand yield of granite generally ranges between 30% and 50%, meaning that each ton of granite can produce 0.3–0.5 tons of manufactured sand. However, the actual yield may vary depending on production conditions.

(1) Hardness and Toughness

The higher the hardness of the granite, the more difficult it is to crush, resulting in a lower sand yield. In contrast, relatively softer granite with lower toughness tends to have a higher yield, as it is easier to break down into fine particles.

(2) Feed Size

Feed size plays an important role in sand yield. Larger granite pieces are more difficult to crush and require greater force and energy to process, leading to lower efficiency and increased equipment wear. Therefore, it is recommended to select appropriately sized raw materials to balance efficiency and energy consumption.

(3) Mineral Composition

Granite containing higher amounts of mica, feldspar, or quartz may affect crushing efficiency and reduce sand yield, as these minerals vary in hardness and breakage behavior.

2. Configuration of a Granite Sand Production Line

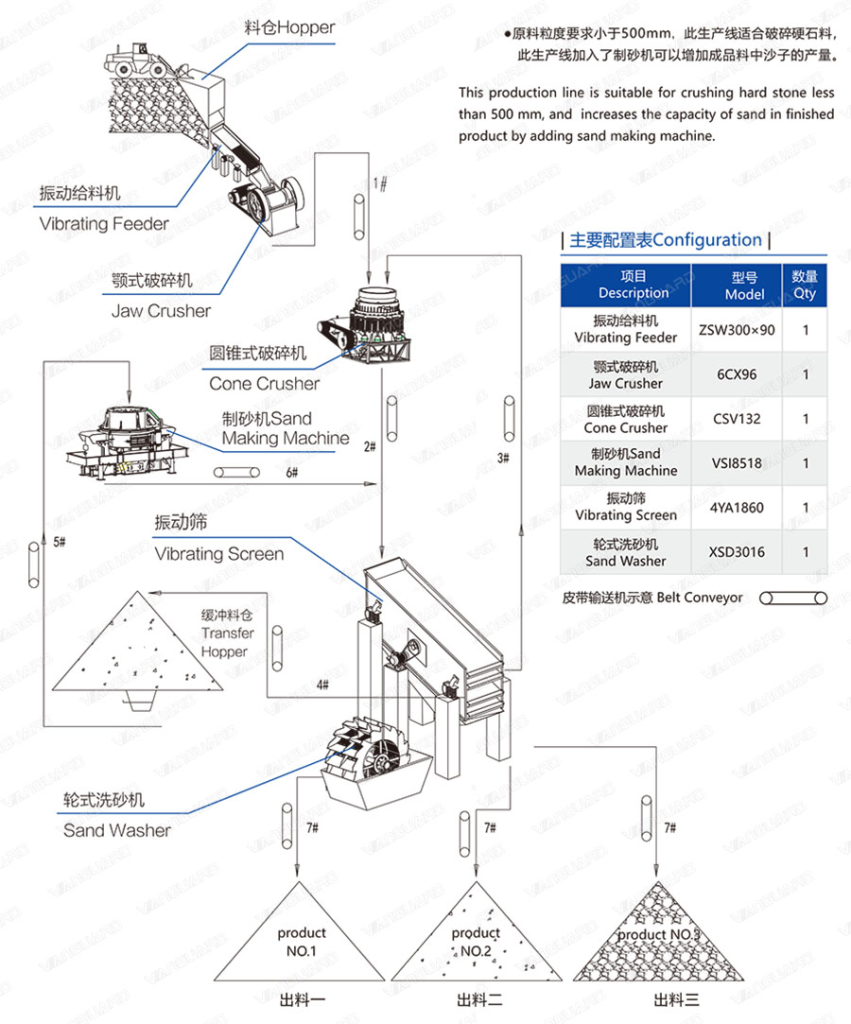

A standard granite sand production line typically includes:

Vibrating feeder → Jaw crusher → Cone crusher → Sand making machine → Vibrating screen → Sand washing machine,

along with auxiliary equipment such as belt conveyors and dust collectors.

When configuring a granite sand production line, several factors must be considered — including production capacity, raw material characteristics, and final product requirements.

- For small-scale production with relatively fine feed materials, a fine jaw crusher can replace a cone crusher for secondary and tertiary crushing.

- For large-scale operations, cone crushers are essential to achieve production capacities of up to several hundred or even thousands of tons per hour.

- Budget is also a key factor — when investment is limited, alternative configurations can be adopted to balance cost and output.

3. Optimization and Layout

Efficient production depends on a well-optimized process layout. A “more crushing, less grinding” approach can improve overall performance by reducing unnecessary grinding energy.

Adding equipment such as fine sand recovery systems can also help increase yield and reduce material loss.

Adjustments can be made based on desired output:

- To produce finer sand, add additional sand-making and washing stages.

- To increase sand yield, consider expanding the crushing and sand-making sections.

Production lines can be designed as stationary or mobile, depending on project scale, site conditions, and operational flexibility.

When designing a granite sand production line, it is crucial to:

- Understand granite’s physical characteristics,

- Determine the required production capacity,

- Optimize the process flow,

- Select suitable equipment models,

- Ensure environmental protection and operational safety,

- And evaluate cost–benefit efficiency.

Proper equipment selection and parameter optimization can effectively improve sand yield, reduce production costs, and enhance efficiency — enabling sustainable, stable, and high-quality sand production for long-term development.