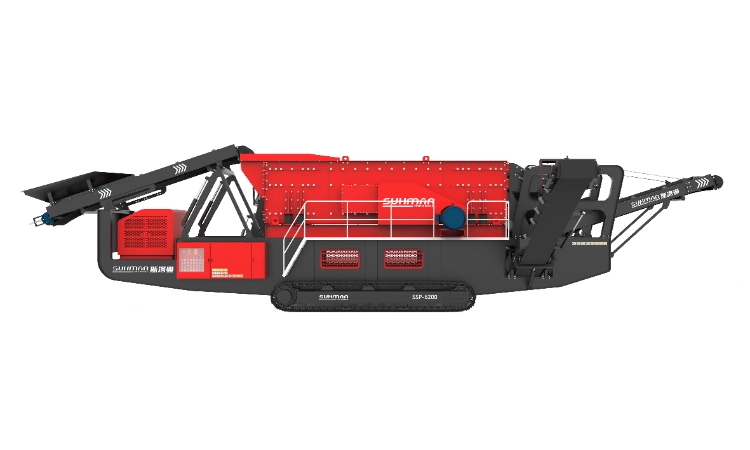

The operational efficiency of the tracked mobile horizontal screening machine is exceptionally high. It incorporates advanced screening technology and a highly efficient driving system, enabling it to quickly complete material screening tasks. Compared to traditional screening equipment, its processing capacity has been significantly enhanced. For instance, in mining operations, it can efficiently screen large amounts of ore in a short period, thereby improving the overall efficiency of the mining process. Additionally, the equipment's high level of automation reduces the need for manual intervention, minimizing the impact of human factors on operational efficiency. Furthermore, its rapid transition capability allows for quick relocation between different work sites, saving time and further boosting productivity.

-

.png)

Energy-Efficient

-

.png)

Suitable For High

Hardness Of Materials -

.png)

High Crushing Efficiency.

Small Wear -

.png)

The Product Particle

Shape Is Good

Working Principle

Application

In construction waste recycling projects, the tracked mobile screening machine is used to screen waste concrete, bricks, and other materials from construction debris, separating aggregates into different particle sizes. These aggregates can then be used to produce recycled building materials, addressing issues such as land occupation and pollution caused by waste stacking. This process not only helps to reduce solid waste but also promotes recycling, delivering both environmental and economic benefits.

In some mining operations, the durable horizontal vibrating screen can move along with the advancing mining face, allowing for on-site screening of ore and reducing transportation costs. Different models of tracked mobile screening machines may vary in processing capacity, screening particle size, and other specifications. These machines can be selected and configured based on specific operational requirements and site conditions.

Product Parameter

| Serial number | Project | Description | SSP-6200 |

| 1 |

Feeding equipment |

Hopper volume(m³) | 5 |

| 2 | Feed capacity (t/h) | 300-500 | |

| 3 | Power of Feeder | 11 | |

| 4 | Vibrating screen | Screen size (length x width)(mm) | 6200×1930 |

| 5 | Maximum feeding granularity(mm) | 100 | |

| 6 | Processing capacity(t/h) | 300-500 | |

| 7 | Power(kw) | 15kw×3 | |

| 8 | The number of screen layer (layer) | 3 | |

| 9 | Feeding belt | Width/length (mm) | 1000×20150 |

| 10 | Power(kw) | 11 | |

| 11 | Side belt conveyor 1 | Width/length (mm) | 550×14300 |

| 12 | Discharge height(mm) | 2800 | |

| 13 | Power(kw) | 5.5 | |

| 14 | Side belt conveyor2 | Width/length (mm) | 550×14300 |

| 15 | Discharge height(mm) | 2800 | |

| 16 | Power(kw) | 5.5 | |

| 17 | Side belt conveyor 3 | Width/length (mm) | 550×9800 |

| 18 | Discharge height(mm) | 2600 | |

| 19 | Power(kw) | 5.5 | |

| 20 | Belt conveyor under screen | Width/length (mm) | 1000×14500 |

| 21 | Discharge height(mm) | 3200 | |

| 22 | Power(kw) | 7.5 | |

| 23 | Track system | Country of origin | England |

| 24 | Brand | Strickland | |

| 25 | Specification length x width(mm) | 4000×400 | |

| 26 | Maximum inclination of walking (°) | 30 | |

| 27 | Walking speed(km/h) | 0.8-1.5 | |

| 28 | Accessories brand | Control System (electrical) | Chuan Ken |

| 29 | Walking system | Strickland | |

| 30 | Conveyor belt | Qingdao Global | |

| 31 | Hydraulic machinery | Bomke | |

| 32 | The engine | CUMMINS | |

| 33 | Steel | Models | Q355B(Materials used for warships) |

| 34 |

The whole machine |

Weight(t) | 37t |

| 35 | Shipping dimensions(mm) | 14300×3630×3850 | |

| 36 | Working size(mm) | 13100×12000×5000 |

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)