mobile crusher screening plant

Release time: 2025-03-31

What Is a Mobile Crusher Screening Plant?

A mobile crusher screening plant is an all-in-one machine designed to crush large materials into smaller sizes and screen them into specific fractions—all while being easily movable between job sites. Unlike stationary plants, their mobility makes them ideal for projects requiring on-site material processing, reducing transportation costs and time.

These plants typically consist of:

- A crusher (e.g., jaw, impact, or cone) to break down materials.

- A screening unit to sort the crushed output by size.

- A chassis for portability, often mounted on tracks or wheels.

They’re widely used in:

- Construction: Processing concrete, asphalt, and demolition debris.

- Mining: Crushing ores like gold, copper, or iron.

- Recycling: Turning waste into reusable aggregates.

For a closer look at crushers, check out our guide on what a crusher is.

Types of Mobile Crusher Screening Plants

Mobile crusher screening plants vary based on the type of crusher they employ. Here’s a breakdown of the most common configurations:

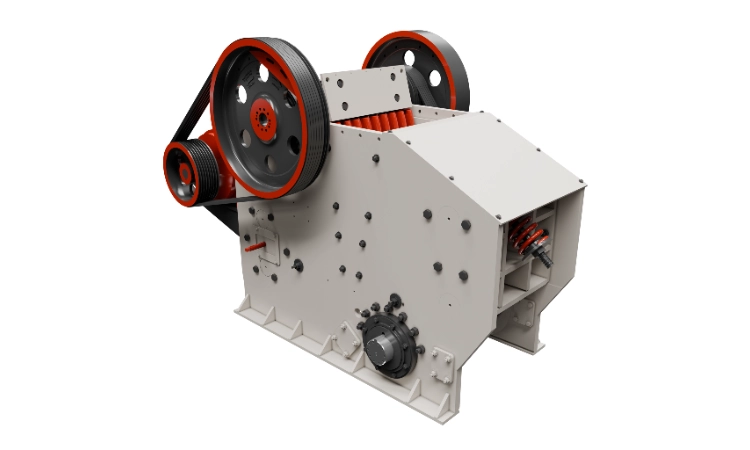

1. Jaw Crusher Screening Plants

- Purpose: Primary crushing of hard materials like granite or basalt.

- Features: Uses compressive force with two jaws—one fixed, one moving.

- Best for: Quarries, mining, and initial material reduction.

- Learn More: Explore jaw crusher vs. gyratory crusher for a detailed comparison.

2. Impact Crusher Screening Plants

- Purpose: Secondary crushing of softer materials like limestone or recycled concrete.

- Features: Employs high-speed impact to shatter materials.

- Best for: Construction, recycling, and producing uniform aggregates.

- Learn More: See how they work in our impact crusher working principles article.

3. Cone Crusher Screening Plants

- Purpose: Tertiary crushing for fine aggregates.

- Features: Uses a rotating cone to crush hard, abrasive materials.

- Best for: Mining, asphalt production, and high-quality output.

Each type integrates a screening system to ensure the final product meets size specifications, making them versatile for diverse applications.

Benefits of Mobile Crusher Screening Plants

Why choose a mobile crusher screening plant? Here are the top advantages:

- Portability: Move the plant to any site, eliminating the need to transport raw materials.

- Time and Cost Savings: Reduces logistics costs and speeds up project timelines.

- Efficiency: Combines two processes (crushing and screening) in one machine.

- Versatility: Adapts to various materials, from rock to recyclables.

- Eco-Friendly: Lowers fuel use and emissions by minimizing equipment needs.

These benefits make them a go-to choice for modern operations. Discover more about mobile solutions at what are mobile crushers.

How Do Mobile Crusher Screening Plants Work?

The operation of a mobile crusher screening plant is both simple and efficient. Here’s the step-by-step process:

- Material Feeding: Raw materials are loaded into a hopper.

- Crushing: The crusher reduces the material into smaller pieces.

- Screening: A vibrating screen sorts the crushed material into different sizes.

- Output: Sorted materials are stockpiled or conveyed for use.

This streamlined process happens on-site, saving resources and boosting productivity. For a deeper dive, visit our page on mobile screening plants.

Applications of Mobile Crusher Screening Plants

These machines shine across multiple industries:

- Construction: Crushing concrete and asphalt for road building or reuse.

- Mining: Processing ores directly at the extraction site.

- Recycling: Converting waste materials into valuable aggregates.

Their adaptability makes them essential for projects of all sizes. Browse specific use cases in our mobile crushing plant category.

Maintenance Tips for Mobile Crusher Screening Plants

Regular maintenance ensures longevity and performance. Follow these tips:

- Inspect Daily: Look for wear, leaks, or loose components before operation.

- Lubricate: Keep bearings and moving parts well-oiled to prevent friction damage.

- Clean Screens: Remove debris to maintain screening efficiency.

- Replace Parts: Swap out worn crusher components (e.g., jaws or cones) promptly.

For a full maintenance routine, download our crusher maintenance checklist.

Why Choose Suhman’s Mobile Crusher Screening Plants?

At Suhman Crusher, we offer cutting-edge mobile crusher screening plants designed for durability and performance:

- Innovative Design: Features automation for ease of use.

- Robust Build: Engineered to handle tough conditions.

- Custom Options: Tailored to your specific needs.

Explore our offerings in the mobile screening plant category.

Conclusion

Mobile crusher screening plants are a smart investment for any operation needing efficient, flexible material processing. By integrating crushing and screening into a portable unit, they save time, reduce costs, and support sustainable practices. Whether you’re in construction, mining, or recycling, these machines can elevate your productivity.

Ready to take the next step? Contact us for expert guidance or dive into our crushing and screening solutions to find the perfect fit for your project.