Introduction

Mobile crushers have reshaped the mining and quarrying industries by offering flexible, efficient solutions for processing materials directly at the source. The concept originated in a German limestone quarry, where the first mobile crusher utilized continuous belt conveyor systems to bypass costly road construction on wet terrain. Today, over 70% of mobile crusher installations are in limestone quarries, handling less than 1,000 tons per hour (TPH) and receiving material straight from excavators at the mining face.

Types of Mobile Crushers

Mobile crushers vary based on mobility and operational needs. Below are the primary types and their key features:

Mobile Crusher

Fully mobile crushers are fed directly by excavators at the mining face and use integrated conveyors to track the main conveyor as mining advances, ensuring maximum flexibility.

- Common Use: Limestone quarries, open-pit mines.

- Related Product: Discover the Advantages of Crawler-Type Mobile Impact Crusher Produced in China.

Semi-Mobile Crusher

Semi-mobile crushers are relocated less often than fully mobile units, balancing mobility with operational stability.

- Application: Large mining operations with periodic moves.

- Learn More: Explore the Mobile Impact Crusher Plus with Higher Stone Output.

Movable Crusher

Positioned centrally in the mine, movable crushers are shifted every few years using specialized equipment to stay near the mining face.

- Key Feature: High capacity with limited mobility.

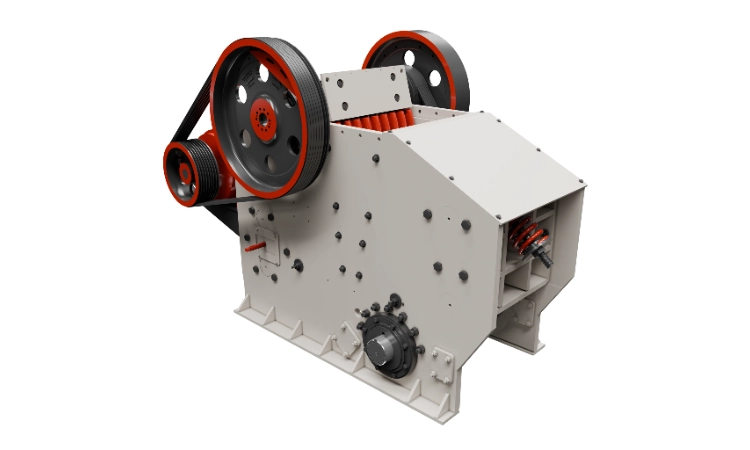

- Related Product: Check out the Mobile Jaw Crusher for Hard Rock.

Portable Crusher

Portable crushers can be disassembled and transported via roads, making them ideal for frequent relocations, such as in construction projects.

- Application: Construction and demolition waste processing.

- Learn More: See the Efficient Mini Modular Jaw Crusher.

Modular Crusher

Modular crushers feature lightweight modules that can be reassembled at new sites within 30 days, suitable for semi-permanent setups.

- Use Case: Medium-term quarry projects.

- Related Product: Learn about the Application of the Efficient and Multifunctional Modular Cone Crusher in Quarries.

Semi-Fixed Crusher

Installed on steel platforms to reduce concrete costs, semi-fixed crushers are moved every 10+ years, offering stability for long-term operations.

- Application: Long-term mining projects.

- Explore More: Visit the Highly Efficient Horizontal Screener.

Table 1: Comparison of Mobile Crusher Types

| Type | Mobility | Relocation Frequency | Typical Application |

|---|---|---|---|

| Mobile Crusher | High | Frequent | Limestone quarries, open-pit |

| Semi-Mobile | Medium | Every few months | Large mining operations |

| Movable Crusher | Low | Every few years | Central mine operations |

| Portable Crusher | High | As needed | Construction, demolition |

| Modular Crusher | Medium | Every 3-5 years | Medium-term projects |

| Semi-Fixed | Very Low | Every 10+ years | Long-term mining projects |

Benefits of Mobile Crushers

Mobile crushers provide significant advantages over traditional fixed systems:

- Cost Savings: By processing materials on-site, they eliminate truck haulage, which can account for up to 50% of mining costs.

- Flexibility: Easily repositioned to follow mining progress, reducing transport distances.

- Energy Efficiency: Belt conveyors paired with mobile crushers use less energy than trucks.

- Reduced Labor: Fewer operators are required, enhancing productivity.

These benefits position mobile crushers as a smart, adaptable solution for modern mining and quarrying.

Applications of Mobile Crushers

Mobile crushers serve a range of industries, including:

- Mining: Efficiently process ore at the mining face.

- Quarrying: Predominantly used in limestone and aggregate production.

- Construction: Recycle demolition waste on-site.

For combined crushing and screening solutions, explore the Mobile Crushing and Screening Integrated Machine.

How Mobile Crushers Work

Mobile crushers are self-contained units mounted on frames, moved by crawlers, wheels, or walking pads. Material is fed via shovels or loaders, crushed, and transported by conveyors to further processing stages.

Mobility Mechanisms

- Crawlers: Travel at 300-500 m/h, suitable for rough terrain, with a soil pressure of 10-20 N/cm².

- Wheels: Move at 500-1000 m/h on stable ground, with a soil pressure of 40-90 N/cm².

- Walking Pads: Operate at 60 m/h, highly stable on all terrains, with a soil pressure of 15-25 N/cm² and low maintenance.

Case Study: Fujiwara Quarry

At Japan’s Fujiwara quarry, a central-shaft mobile crushing plant (MCP) processes 350,000 tons per month. Limestone is crushed to -250 mm, dropped into a shaft, and reduced to -110 mm, showcasing high efficiency and cost-effectiveness.

High-Capacity Mobile Crushers

For operations requiring 4,000-6,000 TPH, semi-mobile gyratory crushers are ideal. Positioned near the mining area and fed by trucks, these units are relocated every 6 months to 2 years using crawlers or transporters capable of handling up to 1,000 metric tons.

Conclusion

Mobile crushers have revolutionized material processing in mining, quarrying, and construction by delivering flexibility, efficiency, and significant cost reductions. From highly mobile units for frequent moves to semi-fixed options for long-term projects, selecting the right type can optimize your operations. Explore our offerings, like the Mobile Jaw Crusher Plus with Powerful Crushing Ability, to find the best solution for your needs.