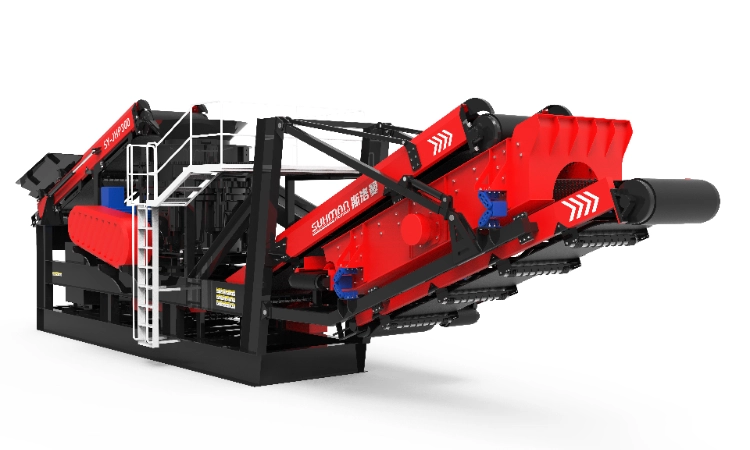

The tracked mobile impact crushing and screening integrated machine is designed to crush and screen materials directly on-site, eliminating the need for transporting materials to separate crushing and screening locations. This significantly reduces transportation costs. The machine is known for its reliable performance and ease of maintenance, offering simple operation that helps minimize downtime for repairs and maintenance.

Additionally, the crushing and screening equipment incorporates various environmental protection measures during its operation. For example, it is equipped with dust suppression devices to reduce dust pollution, ensuring compliance with environmental standards and promoting a cleaner working environment.

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)

.png)

.png)

.png)

.png)