About SUHMAN

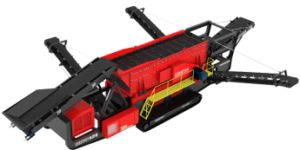

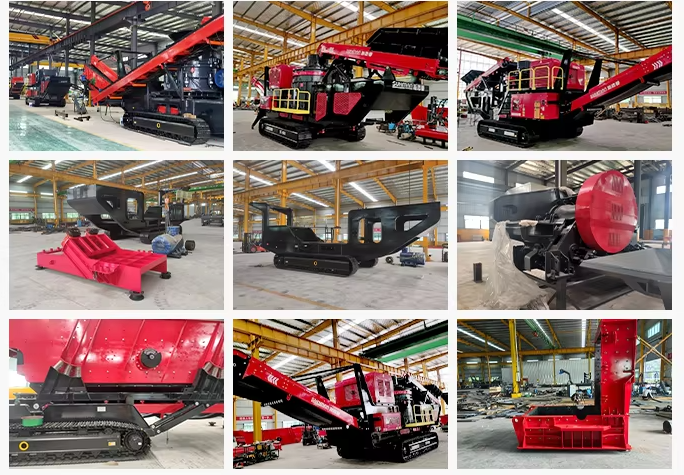

SUHMAN Machinery, headquartered in Hefei, China, is a manufacturer specializing in the R&D and production of fully track-mounted mobile crushing and screening equipment. Our core mission is to provide modular, transport-friendly solutions for stone processing, construction waste recycling, infrastructure projects, and municipal demolition work.

Our systems support combinations such as jaw-cone-screen or jaw-impact-screen mobile trains, tailored to project needs. All machines are CE-compliant, compact in transport dimensions, and equipped for quick commissioning on job sites.

SUHMAN has delivered equipment to customers in the Middle East, Russia, Latin America, and Southeast Asia. We offer full English-language technical support, spare parts supply, and dealer/OEM customization services.

If you are looking for a reliable mobile crusher supplier with field-proven equipment and responsive service, SUHMAN is ready to support your business.

- Mobile Crushing Plants

- Mobile Screening Plants

- Dual-Core Jaw Crushers

- Crawler Impact Crushers / Cone Crushers / VSI Units

- Heavy-duty Scalpers & Screening Machines

| Model | Type | Max Feed Size | Capacity (t/h) | Power (kW) | Key Features |

|---|---|---|---|---|---|

| SE-650D | Mobile Jaw Crusher | 500 mm | 50–130 | 92 | Compact design for primary crushing. |

| SE-1060 | Mobile Jaw Crusher | 630 mm | 100–250 | 160 | High throughput, suitable for large operations. |

| SY-HP200 | Mobile Cone Crusher | 200 mm | 150–350 | 250 | Efficient secondary crushing. |

| SY-HP300 | Mobile Cone Crusher | 200 mm | 150–350 | 250 | Higher capacity and versatile use. |

| SF-380D | Mobile Impact Crusher | 950 mm | 80–260 | 246 | Versatile impact crushing for various materials. |

| SZ-450D | Mobile Scalper | N/A | 200–500 | 56 | Heavy-duty screening for large operations. |

| SSP-6200 | Mobile Screening Plant | N/A | 220–400 | 69 | High-efficiency screening for various materials. |

SUHMAN specializes in designing and manufacturing a full range of track-mounted mobile crushing and screening equipment for mining, quarrying, construction, and recycling industries. Our machines are built for flexibility, reliability, and productivity in demanding site conditions.

🔹 Core Product Lines

-

Mobile Jaw Crushers (SE Series)

Primary crushers designed to handle large feed sizes (up to 900mm), ideal for first-stage crushing of hard stone, blasted rock, and demolition debris. Compact models (SE-650) suit small sites, while SE-1060 and above handle higher capacities (100–350 TPH). -

Mobile Cone Crushers (SY-HP Series)

Secondary and tertiary crushers with hydraulic adjustment and over-iron protection. Excellent for granite, basalt, and other hard materials where shape and gradation control are essential. -

Mobile Impact Crushers (SF Series)

Versatile units ideal for soft to medium-hard rock (like limestone) and recycling applications. Equipped with pre-screening, magnetic separation, and reversible conveyors for handling concrete with rebar. -

Mobile VSI Sand Makers (SV Series)

For producing high-quality artificial sand and fine aggregates. Common in highway and infrastructure applications requiring precise particle size. -

Mobile Screening Plants (SSP Series)

Heavy-duty incline and horizontal screens with multiple decks. Used for final product sorting, scalping before crushing, or dewatering. -

Mobile Scalping Plants (SZ Series)

Designed for rough screening of overburden, topsoil, and heavy construction material. Often used in primary separation before crushing.

🔹 Features & Advantages

-

Integrated diesel-hydraulic drive with electric/hybrid options available

-

Remote-controlled movement and auto-leveling outriggers for fast setup

-

Modular designs allow multi-stage “crushing trains” (e.g. jaw + cone + screen)

-

80–450 TPH rated capacities depending on configuration and material

-

Reinforced frames, anti-dust enclosures, and high-wear steel linings

-

Compatible with international shipping and containerized transport

🔹 Common Output Applications

-

Aggregates (0–5 mm, 5–10 mm, 10–20 mm, 20–31.5 mm)

-

Railway ballast, road base, concrete mix, asphalt fill

-

Recycled crushed concrete, brick, C&D waste

-

Artificial sand (VSI systems)

SUHMAN mobile crushers and screens are used in construction, mining, infrastructure, and demolition/recycling projects. They are designed for high mobility and modular flexibility to perform effectively in complex site conditions.

Video Demonstration

The video below shows a SUHMAN mobile crusher in operation:

Why Partner with SUHMAN

- Brand Authority: Subsidiary of Anhui Dongfeng Electromechanical Co., Ltd., with multiple patents and recognized certifications.

- Complete Product Range: Offers a wide range of mobile crushing and screening equipment, covering coarse, medium, and fine crushing and screening processes.

- Technical Innovation: Advanced manufacturing and R&D capabilities with ongoing product development.

- Engineering Solutions: Provides project support including process design and modular equipment configuration.

- Flexible Business Model: Supports equipment sales and, where available, flexible leasing options.

- Wide Market Applications: Suitable for construction, mining, infrastructure, and waste recycling industries.

- Comprehensive Support: Offers support in marketing, operations, training, logistics, and after-sales service.

Product Highlights & Applications

- Mobile Crushing Plant – Ideal for quarries and mining operations requiring high capacity and rapid mobility.

- Mobile Screening Plant – Efficient for grading, dewatering, and optimizing product size in aggregate and recycling applications.

- Dual-Core Jaw Crusher – Designed for crushing high-hardness rock with strong compressive strength.

- Crawler Impact / VSI / Cone / Scalper / Screening Machines – Completes the crushing and screening workflow, adaptable to complex materials and environments.

| Feature | Description |

|---|---|

| Brand Authority | Subsidiary of Anhui Dongfeng Electromechanical Co., Ltd., with multiple patents and recognized certifications. |

| Complete Product Range | Wide range of mobile crushing and screening equipment, covering all crushing and screening processes. |

| Technical Innovation | Advanced manufacturing and R&D capabilities with continuous product improvement. |

| Engineering Solutions | Project support including process design and modular equipment configuration. |

| Flexible Business Model | Supports equipment sales and, where available, flexible leasing options to suit local market needs. |

| Wide Market Applications | Suitable for construction, mining, infrastructure, and waste recycling industries. |

| Comprehensive Support System | Support in site setup, marketing, operations, training, logistics, and after-sales services. |

SUHMAN crushers and screening machines perform well in construction projects, mining sites, urban redevelopment, and demolition/recycling applications.

Video: SUHMAN Applications

The following video highlights SUHMAN equipment in various applications:

How to Join SUHMAN

- Inquiry & Consultation – Contact the SUHMAN partnership team for program information.

- Presentation – Visit headquarters or attend an online session to learn about the technology, products, and business model.

- Submit Application – Provide company profile and market plan for evaluation.

- Contract Signing – Formalize the partnership agreement and begin implementation.

- Setup & Training – Receive support for site setup and team training.

- Launch & Support – Start operations with ongoing guidance from SUHMAN headquarters.

Partner Requirements

- Legally registered company or individual with independent business capability.

- Alignment with SUHMAN’s brand strategy and quality standards.

- Sufficient capital and local market resources.

- Prior experience or network in construction, mining, or heavy machinery is preferred.

- Commitment to uphold SUHMAN’s brand image and operational guidelines.

Partner Benefits

The global demand for mobile crushing and screening equipment is growing with infrastructure, mining, and recycling industries. By partnering with SUHMAN, you gain:

- An established international brand

- Continuous technical and product support

- Comprehensive marketing, logistics, and operational guidance

- A dual-track business model (equipment sales and leasing)

Contact Us

For more information or to inquire about a partnership, please contact SUHMAN:

- Phone/WhatsApp: +86 136 5555 0150

- Email: info@suhmancrusher.com

- Address: No. 43 Tangkou Road, Feixi County, Hefei City, Anhui Province, China

Frequently Asked Questions (FAQ)

1. What types of mobile crushing configurations do you offer?

We provide modular trains including mobile jaw crushers, cone crushers, impact crushers, scalpers, and finishing screens. Units can run standalone or as a full train.

2. How do I choose between a jaw-cone train and a jaw-impact train?

Jaw-cone is ideal for hard, abrasive rock (granite/basalt) and high-quality aggregates. Jaw-impact fits softer rock (limestone) or recycling where cubic shape is prioritized.

3. What capacity range can your mobile crushing plants cover?

Typical mobile plants cover roughly 80–450 TPH depending on material hardness, feed size, and final products. We size the train to your project targets.

4. What feed size and final products can I get?

Max feed is model-dependent (often up to 600–900 mm). Common outputs include 0–5, 5–10, 10–20, 20–31.5 mm, or custom blends by adjusting crusher settings and screen media.

5. Can your mobile crushers handle rebar concrete and C&D waste?

Yes. We can add pre-screening, magnet separation, and reinforced wear packages for recycling applications.

6. How long does installation and commissioning take?

Most units are production-ready within hours after offload. Full train commissioning usually takes 1–3 days depending on complexity. Training is provided.

7. What power options are available?

Standard diesel-hydraulic drive is available, with electric/hybrid options for sites needing lower operating cost or emissions control.

8. What are the operating cost factors?

Key drivers are wear parts (jaw plates, mantles/concaves, blow bars), fuel/electricity, and labor. Proper pre-screening and correct chamber selection greatly reduce cost per ton.

9. What after-sales support do you provide?

We offer spare parts supply, remote diagnostics, on-site service if needed, and maintenance plans to minimize downtime.

10. Do you offer customization?

Yes. We can customize the configuration to match your project needs, including:

-

Crusher chambers and wear packages matched to your rock type and abrasiveness

-

Screen media options and deck layouts for your target gradation

-

Feeder, hopper, and conveyor setups to suit your site layout and workflow

11. What maintenance does the Dual-Core Jaw Crusher require?

To keep the machine running at peak performance, we recommend:

-

Routine inspections: Check jaw plates, toggle, bearings, and fasteners for wear or looseness.

-

Lubrication: Grease bearings and moving parts on schedule.

-

Hydraulic system monitoring: Inspect oil level, pressure, and hoses.

-

Wear parts management: Replace jaw plates and liners on time to avoid downtime.

We provide detailed maintenance manuals and technical support.

12. What is the warranty period for SUHMAN products?

All SUHMAN products come with a standard 2-year warranty covering defects in materials and workmanship. Extended warranty and service packages are available.