-

.png)

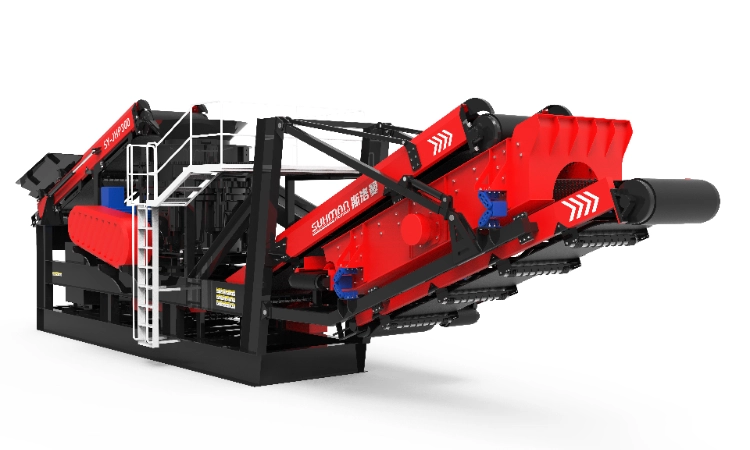

Energy-Efficient

-

.png)

Suitable For High

Hardness Of Materials -

.png)

High Crushing Efficiency.

Small Wear -

.png)

The Product Particle

Shape Is Good

Working Principle

Application

Product Parameter

| Project | Name | SF-580D |

| Feed section | Feeding capacity (t/h) | 300 |

| Hopper volume (m³) | 6 | |

| Power (kw) | 4.5×2 | |

| Feeder size (length x width) (mm) | 3950x1460 | |

| Feeding height (mm) | 3850 | |

| Crusher | Crusher model | 1315 |

| Feed inlet size (length x width) (mm) | 1540x1100 | |

| Maximum feed particle size (mm) | <700 | |

| Adjustment range of discharge port (mm) | 300-500\0-150 | |

| Crusher weight (t) | 23 | |

| Crusher power (kw) | 315 | |

| Main belt | Length x Width (mm) | 11300×1600 |

| Unloading height (mm) | 3250 | |

| Power (kw) | 9.5×2 | |

| Belt for finished materials | Length x Width (mm) | 5200×1350 |

| Unloading height (mm) | 2860 | |

| Power (kw) | 7.2×2 | |

| Return material hanging sieve | Length x Width (mm) | 4600×2160 |

| Power (kw) | 3.7×2 | |

| Number of sieve layers (layers) | 1 | |

| Screen size (mm) | 4000×1540 | |

| Transition belt | Length x Width (mm) | 1750×970 |

| Power (kw) | 3 | |

| Return conveyer belt | Length x Width (mm) | 7200×970 |

| Power (kw) | 5.5 | |

| De-ironing separator | Length x Width (mm) | 2100×910 |

| Power (kw) | 3 | |

| Complete machine | Track chassis model | LDZ55-3657 |

| Engine power (kw) | 100 | |

| Whole machine weight (t) | 53 | |

| Machine processing capacity (t/h) | 180-230 | |

| Total power of crushing work (kw) | 378.1 | |

| Working dimensions (length, width, height/mm) | 15932×3700×4100 | |

| Transportation dimensions (length, width, height/mm) | 15932×3500×3900 |

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)