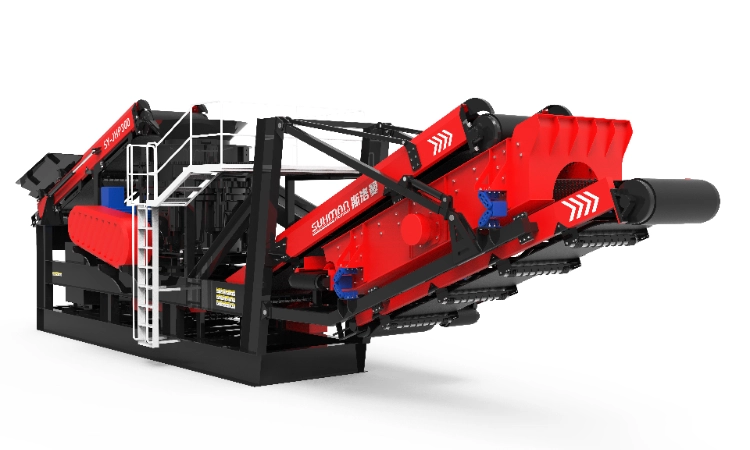

Why Choose the SE-1060 Tracked Jaw Crusher?

The SE-1060 is a high-performance primary crushing station engineered specifically for hard rock applications like granite, basalt, and river stone. Integrating a heavy-duty vibrating feeder, a high-capacity jaw unit, and discharge conveyors onto a compact crawler chassis, it offers a perfect balance of power and mobility.

Key Advantages:

- 1. Rapid Deployment & Installation

The fully integrated design eliminates the need for concrete foundations. With hydraulic folding conveyors and a compact layout, the SE-1060 can be set up and ready to crush within hours of arriving on site, significantly reducing crane usage and labor costs. - 2. Superior Site Mobility

Built on a heavy-duty tracked chassis, the SE-1060 can navigate rough terrain and climb slopes that wheel-mounted units cannot. It can move directly to the blasting face, reducing the distance haul trucks need to travel. - 3. Reduced Operational Costs

By crushing directly at the source, material handling costs are minimized. The machine's fuel-efficient design and optional external power connection (Dual-Power) further reduce cost-per-ton. - 4. Versatile & Flexible

Whether operating as a standalone unit or as part of a multi-stage train (with cone crushers and screens), the SE-1060 adapts easily. The optional side conveyor allows for the removal of fines (scalping) before the crusher, improving throughput and reducing wear. - 5. Dual-Power Capability

The integrated diesel generator provides full autonomy in remote locations. Alternatively, the unit can connect to mains electricity for emission-free and low-noise operation in urban environments.

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)

.png)

.png)

.png)