-

.png)

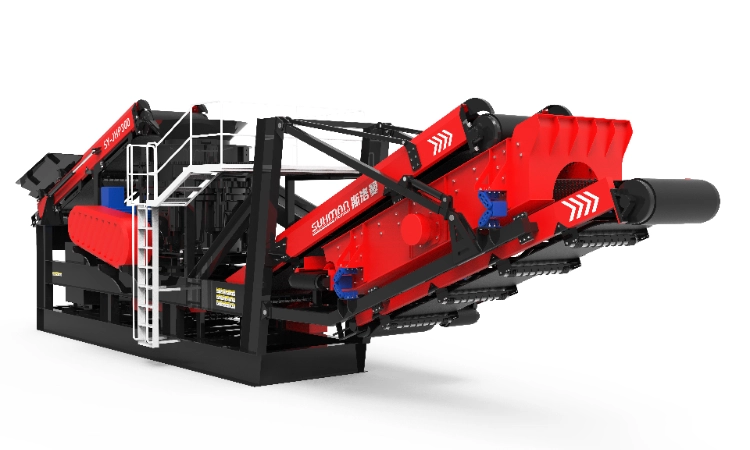

Energy-Efficient

-

.png)

Suitable For High

Hardness Of Materials -

.png)

High Crushing Efficiency.

Small Wear -

.png)

The Product Particle

Shape Is Good

Working Principle

Application

Product Parameter

| Serial number | Project | Description | SE-1160 |

| 1 | Feeding equipment | Hopper volume(m³) | 6 |

| 2 | Feed height(mm) | 4020 | |

| 3 | Maximum feed size(mm) | 800 | |

| 4 | Size of feeder (length x width)(mm) | 4000×1120 | |

| 5 | Feed capacity (t/h) | 170-450 | |

| 6 | Power of Feeder | 3.7kw×2 | |

| 7 | Jaw Crusher | Models | 1160 |

| 8 | Maximum feed particle size (mm) | 800 | |

| 9 | Inlet size (length x width)(mm) | 800×1160 | |

| 10 | Processing capacity(t/h) | 170-450 | |

| 11 | Discharge particle size range(mm) | 0-300 | |

| 12 | Power(kw) | 135 | |

| 13 | Weight(t) | 18.6 | |

| 14 | Main belt conveyor | Width/length (mm) | 1200×23700 |

| 15 | Discharge height(mm) | 3150 | |

| 16 | Power(kw) | 15 | |

| 17 | Iron remover | Models | RCYD-12 |

| 18 | Power(kw) | 3 | |

| 19 | Processing capacity(t/h) | 0-20 | |

| 20 | Size(mm) | 2100*1450*420 | |

| 21 | Weight(kg) | 900 | |

| 22 | Side belt conveyor (Optional) | Width/length (mm) | 550×10300 |

| 23 | Discharge height(mm) | 2760 | |

| 24 | Power(kw) | 3kw | |

| 25 | Track system | Country of origin | England |

| 26 | Brand | Strickland | |

| 27 | Specification length x width(mm) | 4500×500 | |

| 28 | Maximum inclination of walking (°) | 30 | |

| 29 | Walking speed(km/h) | 0.8-1.5 | |

| 30 | Power System (for single walking) | Models | QSB3.9-G3 |

| 31 | Fuel consumption (L/h) | 3.9 | |

| 32 | Power(kw) | 79 | |

| 33 | Tank volume(L) | 200 | |

| 34 | Emission standards | National III | |

| 35 | Power System -LRB-both oil and electricity) | Models | 6TAA8.9-G3(CUMMINS) |

| 36 | Fuel consumption (L/h) | ||

| 37 | Power(kw) | 255 | |

| 38 | Tank volume(L) | 600 | |

| 39 | Emission standards | National III | |

| 40 | Accessories brand | Control System (electrical) | Chuan Ken |

| 41 | Walking system | Strickland | |

| 42 | Conveyor belt | Qingdao Global | |

| 43 | hydraulic machinery | Bomke | |

| 44 | The engine | CUMMINS | |

| 45 | Steel | Models | Q355B(Materials used for warships) |

| 46 | The whole machine | Weight(t) | 48 |

| 47 | Shipping dimensions(mm) | 14850×3400×4020 | |

| 48 | Working size(mm) | 14850×3400×4020 |

info@suhmancrusher.com

info@suhmancrusher.com

.png)

.png)