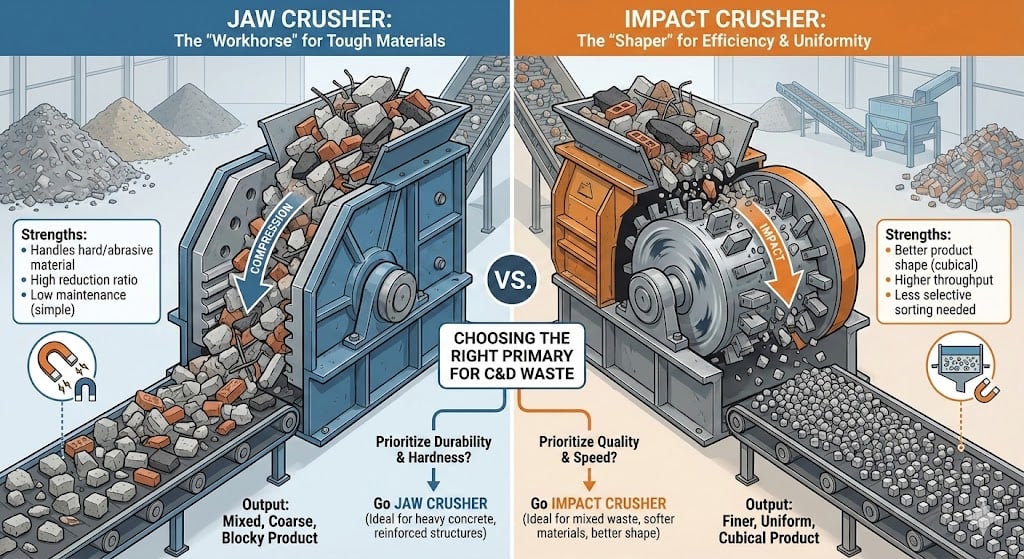

Jaw Crusher vs. Impact Crusher: Choosing the Right Primary Crusher for C&D Waste

Handling reinforced concrete is the toughest part of C&D recycling. The steel inside wants to destroy your crusher, and abrasive materials eat away at your wear parts. Your choice of primary crusher decides how you handle these challenges.

It usually comes down to a choice between compression (a Мобильная щековая дробилка) and impact (a Мобильная ударная дробилка). One handles hard, oversized feed better; the other produces a higher-value sellable aggregate. We analyze the strengths and weaknesses of both to help you match the right machine to your material.”

1. Mobile Jaw Crusher

Щековые дробилки использовать compression force to break material between a fixed and a moving manganese plate.

Why choose it for C&D Waste?

- Handling Oversized Feed: If your waste stream includes massive concrete slabs, bridge pillars, or large foundation blocks, a Jaw crusher (like the SUHMAN Dual-Core series) is indispensable. It has a larger feed opening relative to its size.

- Низкие эксплуатационные расходы: Jaw plates wear down much slower than impactor blow bars. If your concrete has high “abrasiveness” (e.g., contains high-silica river gravel), the jaw crusher will save you a fortune in wear parts.

- Надежность: It is less sensitive to uncrushable items that occasionally slip through pre-sorting.

The Trade-off:

- Output Shape: The crushed material can be “flaky” or elongated, which may not meet premium road-base specifications without secondary processing.

- Rebar Liberation: While it breaks the concrete, it doesn’t always “strip” the rebar cleanly, making magnetic separation slightly less efficient.

2. Mobile Impact Crusher

Impactors use high-speed kinetic energy. Blow bars on a spinning rotor fling the material against impact plates (aprons), shattering it along natural cleavage planes.

Why choose it for C&D Waste?

- Superior Grain Shape: If you are selling recycled aggregate for high-grade concrete or asphalt, the Impact crusher is king. It produces a cubical, high-quality product за один проход.

- Excellent Rebar Liberation: The violent impact force is highly effective at shaking concrete loose from steel reinforcement. This allows your overbelt magnet to recover clean, high-value scrap metal.

- Высокий коэффициент редукции: It can often turn large waste into a finished product size in one step, potentially eliminating the need for a secondary crusher.

The Trade-off:

- Wear Costs: If the feed is highly abrasive, the blow bars will wear out quickly, increasing your cost-per-ton.

Technical Comparison

| Особенность | Мобильная щековая дробилка | Мобильная ударная дробилка |

| Принцип дробления | Compression (Squeezing) | Impact (Striking) |

| Primary Strength | Handling hard, oversized blocks | High reduction & cubical shape |

| Rebar Separation | Умеренный | Отлично |

| Wear Part Life | Long / Cost-effective | Short to Medium |

| Лучше всего подходит для | Primary stage of heavy concrete | Brick, asphalt, & high-spec aggregate |

Which SUHMAN Solution Fits Your Site?

At SUHMAN, we don’t believe in one-size-fits-all. Our engineering team recommends selecting your equipment based on your “End Product” goals:

The “Volume” Setup (Durability Priority): If you need to process massive amounts of heavy demolition waste for general fill, the SUHMAN Tracked Mobile Jaw Crusher is your ultimate workhorse. It is engineered for maximum durability and industry-leading low maintenance costs.

The “Premium” Setup (Quality Priority): For contractors aiming to produce “certified recycled aggregate” for high-end construction, the SUHMAN Mobile Impact Crusher delivers the superior cubical grain shape and quality your customers demand.

The “Total” Solution (The Power Duo): For maximum efficiency, many of our global clients deploy a Jaw-Impact Train. The Jaw Crusher handles the initial heavy lifting, while the Impact Crusher refines the shape and ensures 100% metal recovery for a truly closed-loop process.

Get a Tailored Configuration Within 24 Hours

Not sure about the abrasiveness of your material? Our engineers can analyze your feed requirements and provide a detailed TPH (Tons Per Hour) simulation.